Best Practices for Displaying Forklift Vehicle Security Signs in Industrial and Warehouse Setups

The application of efficient forklift vehicle safety signs is important in industrial and warehouse environments, where the threat of accidents can dramatically impact both employees and operations. Secret considerations such as exposure, positioning techniques, and adherence to governing standards are crucial for making best use of the efficiency of these indicators. Additionally, the continuous upkeep and periodic examination of signs can additionally boost security actions - Forklift Truck Safety Signs. The real difficulty exists in balancing these aspects to cultivate not only conformity but additionally an aggressive society of security. What details techniques can organizations take on to ensure their security signs really serves its function?

Value of Security Signs

The relevance of security signs in settings where forklift trucks operate can not be overstated, as these signs play a crucial duty in protecting against crashes and guaranteeing the safety of personnel. Efficient security signage works as a vital interaction tool, conveying crucial information concerning potential dangers related to forklift procedures. This consists of cautions regarding pedestrian zones, rate restrictions, and marked forklift paths, which are vital for maintaining an arranged and risk-free workplace.

Correctly presented safety and security indications can enhance situational recognition among employees, reminding them of the risks associated with their surroundings. They give clear directions on secure methods, such as using appropriate individual protective tools (PPE) and adhering to functional guidelines. Moreover, safety and security signs adds to conformity with governing demands, helping companies prevent penalties and advertise a culture of safety - Forklift Truck Safety Signs.

In addition to their preventive duty, security signs cultivate a feeling of responsibility among staff members. When workers know safety methods and the potential repercussions of neglecting them, they are a lot more likely to take proactive procedures to protect themselves and their coworkers. For that reason, investing in top notch safety and security signage is crucial for any kind of workplace where forklift vehicles function.

Secret Presence Elements

Efficient visibility is critical in making sure the safety of both forklift operators and pedestrians in hectic workplace. To achieve this, a number of crucial exposure factors need to be taken into consideration when designing and placing safety and security indicators.

First, the size and font of the text on the indicator play a crucial role. Larger typefaces boost readability from a range, enabling individuals to quickly understand the message. In addition, using strong and clear typefaces can substantially enhance legibility under numerous lights problems.

Effective Placement Techniques

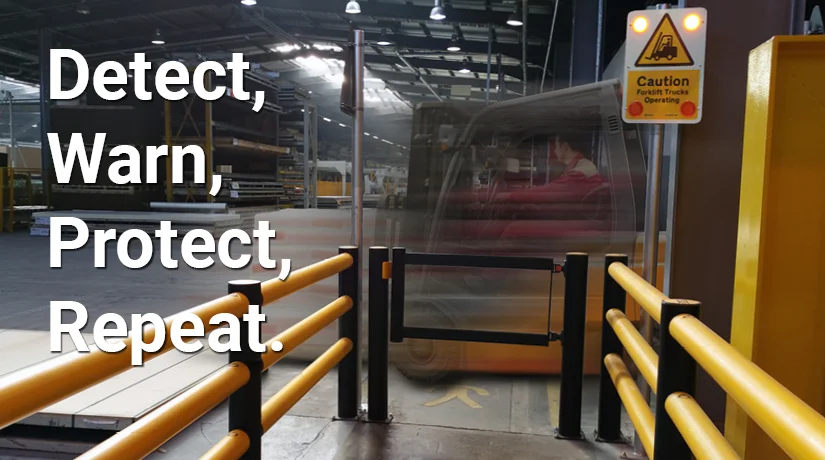

Indicator positioning considerably influences their effectiveness in interacting safety and security messages within forklift operations. To make best use of exposure and understanding, signs ought to be purposefully positioned in areas where forklift task is prevalent. Key places consist of intersections, unseen areas, and near loading and dumping zones, where operators and pedestrians communicate often.

Elevation is another essential element; indications should be placed at eye level to guarantee they are conveniently seen by both forklift drivers and ground employees. Additionally, utilizing contrasting shades and clear graphics will improve presence, specifically in low-light conditions or high-traffic areas.

Consider the flow of website traffic when determining positioning. Indicators must be placed to assist drivers safely and efficiently with the work area, reducing the risk of crashes. Moreover, normal analyses published here need to be carried out to guarantee that signs stay unhampered by tools or supply, as moving layouts can diminish their performance.

Including feedback from workers relating to indicator positioning can also lead to renovations. Engaging personnel in this procedure cultivates a culture of security and find more info recognition, eventually adding to an extra protected workplace. By implementing these efficient positioning methods, organizations can improve interaction and adherence to safety procedures.

Conformity With Laws

Making sure conformity with guidelines is necessary for keeping a secure workplace in forklift procedures. Governing bodies such as the Occupational Safety And Security and Health And Wellness Management (OSHA) and the American National Specification Institute (ANSI) develop standards that dictate the proper use safety and security signs. Adherence to these regulations not just advertises security but also minimizes the threat of charges and legal liabilities.

Forklift safety indicators need to be clearly visible, readable, and purposefully placed according to regulative needs. These indicators need to make use of standardized signs and color codes to share crucial information effectively. For example, yellow suggests care, while red signals risk, guaranteeing that staff members can quickly analyze the check in high-stress situations.

Organizations should conduct routine audits to validate that all safety signage satisfies current legal requirements. By making certain that forklift safety indications adhere to mandated standards, firms cultivate a culture of security understanding amongst employees, thus improving general work environment safety and security and performance.

Normal Upkeep and Updates

Keeping and upgrading forklift security signs is crucial for making certain that they stay effective and pertinent in the work environment. Regular examinations must be conducted to analyze the problem of safety indicators, as exposure to rough industrial environments can bring about fading, damage, or obsolescence. Signs that are no more readable or that include obsolete info can considerably threaten safety and security protocols.

It is essential to establish a routine maintenance routine that includes inspecting the presence and clearness of all safety signage. Any type of indicators that are worn, damaged, or misaligned should be try this without delay replaced or rearranged to keep their performance. Furthermore, as guidelines and security standards develop, it is vital to upgrade signs to reflect current methods and conformity needs.

Engaging workers in security training sessions can additionally enhance the significance of preserving and upgrading safety and security signs. This not only makes sure that every person knows the signs' definitions but likewise promotes a society of security within the office. By focusing on normal maintenance and updates, organizations can create a safer atmosphere and boost the total efficiency of their forklift safety and security signs.

Conclusion

In conclusion, the implementation of ideal techniques for presenting forklift vehicle safety and security indicators is important for improving work environment security in industrial and storehouse atmospheres. By prioritizing exposure, utilizing efficient placement methods, making certain conformity with guidelines, and devoting to routine upkeep, companies can substantially minimize the threat of accidents. Such measures not only communicate hazards efficiently but additionally cultivate a society of safety and security that profits all staff members entailed in forklift procedures.

Tony Danza Then & Now!

Tony Danza Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!